Table of Contents

- 2025 Scrap Metal Market Overview

- Factors Affecting Shredded Scrap Prices

- Role of Shredders in Scrap Recovery

- Recommended Equipment: HB Shredder 7.5 kW Small Double Shaft

- Industry Trends for 2025

- Global Scrap Price Comparison

- Tips to Maximize Shredded Scrap Profits

- Key Summary Table

2025 Scrap Metal Market Overview

In 2025, the global scrap metal market is showing a stable upward trend. With stricter environmental regulations and growing attention to sustainable resource use, the prices of ferrous and non-ferrous metals such as steel, aluminum, and copper continue to rise.

Average Recyclable Metal Prices (Q1 2025):

- Scrap Steel: $300–$420/ton

- Scrap Aluminum: $1000–$1400/ton

- Scrap Copper: $6500–$7800/ton

Especially for companies using shredders for pre-sorting and processing, scrap yields are improved, and pricing leverage increases.

Factors Affecting Shredded Scrap Prices

The price of shredded scrap is influenced not only by market trends but also by operational and equipment-related factors:

1. Type of Material

- Ferrous materials (e.g., appliance shells, steel sheets) tend to have stable pricing.

- Non-ferrous metals (e.g., copper, aluminum) are more volatile but more valuable.

2. Shred Size Consistency

- More uniform and clean shredded material sells for higher prices.

- Modern shredders offer adjustable particle sizes for different applications.

3. Regional Location and Transport Costs

- Local scrapyard prices differ from export markets.

- Efficiency in transport and material density impacts overall profit.

4. Regulatory Compliance

- Whether operations meet environmental regulations and energy standards.

- Proper waste classification and documentation increases legal resale value.

Role of Shredders in Scrap Recovery

Shredders play a critical role in scrap metal recycling, used to break down bulky or composite materials into easily transportable and sortable sizes.

Benefits of Using a Shredder:

- Increases material density and reduces transport cost

- Enables initial separation before magnetic or manual sorting

- Improves purity and resale value of the shredded scrap

Choosing the right shredder is vital to profitability, considering power consumption, processing capacity, safety, and maintenance.

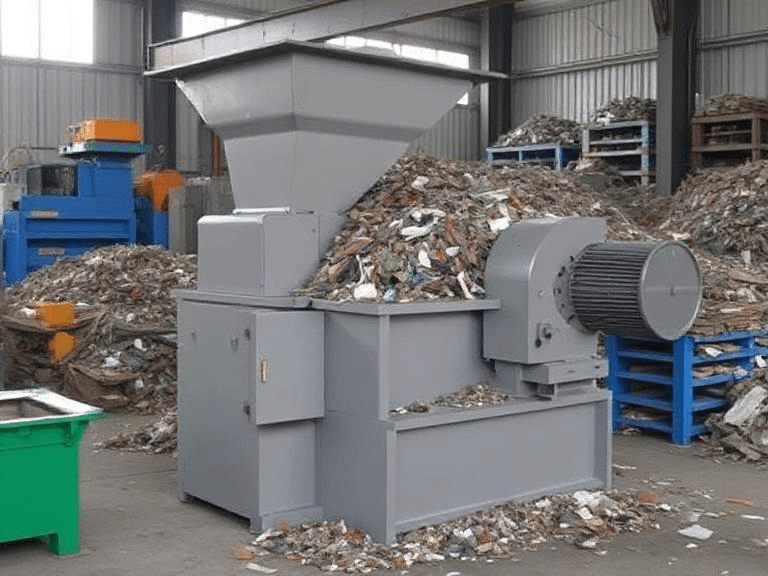

Recommended Equipment: HB Shredder 7.5 kW Small Double Shaft

For small and medium-sized recycling centers and workshops, compact shredders are increasingly popular. Here’s a highly recommended model:

7.5 kW Small Cardboard Double Shaft Shredder

| Specification | Details |

|---|---|

| Brand | HB Shredder |

| Model | Small Cardboard Double Shaft |

| Shredding Capacity | Up to 500 kg/h (depending on material) |

| Power Consumption | 7.5 kW |

| Voltage | 380V / 50Hz (customizable) |

| Dimensions (L x W x H) | 1200mm x 800mm x 1500mm |

| Weight | Approx. 800 kg |

| Shredding Shaft Material | Hardened Steel |

| Shredding Chamber Material | Heavy-Duty Steel |

| Adjustable Shredding Size | 5–50mm (customizable) |

| Control Panel | PLC-based with Touchscreen Interface |

| Safety Features | Safety Guards, Emergency Stop Button |

| Warranty | 12 Months Parts & Labor |

Best Use Scenarios:

- Small and mid-sized metal recycling facilities

- Pre-processing cardboard or composite materials

- Appliance dismantling and e-waste preprocessing

Industry Trends for 2025

Based on 2025 forecasts and data insights, the shredded scrap and recycling industry is expected to evolve in the following ways:

- Automation Rise: Smart control systems like PLC + touchscreens become standard

- Compact & Efficient Machines: Smaller footprints with high output gain popularity

- Eco-Friendly Focus: Energy-efficient and low-noise equipment in high demand

- Export Market Growth: Middle East and South Asia show rising demand for processed scrap

Global Scrap Price Comparison

Scrap Metal Price Comparison by Region (USD/ton)

| Region | Scrap Steel | Scrap Aluminum | Scrap Copper |

|---|---|---|---|

| China | 420 | 1250 | 7500 |

| India | 380 | 1200 | 7200 |

| Europe | 450 | 1350 | 7800 |

| Middle East | 400 | 1100 | 7000 |

From the table, China offers competitive prices for copper and aluminum, making it favorable for both local recycling and export resale.

Tips to Maximize Shredded Scrap Profits

Profit in scrap recovery depends not just on price, but also on efficient operation and process optimization. Here’s how to get the most out of your shredder investment:

- Select the right equipment: HB Shredder 7.5 kW is a powerful and compact option

- Control particle output: Cleaner, consistent output fetches higher rates

- Establish steady buyers: Work with local scrapyards or global buyers to avoid price drops

- Track market prices: Timing your shipments improves returns

- Maintain your shredder: Regular servicing reduces downtime and extends lifespan

Key Summary Table

| Key Point | Summary |

|---|---|

| Scrap Prices | Prices are rising, copper remains the most valuable |

| Shredder Benefits | Improves efficiency, material density, and purity |

| Recommended Equipment | HB Shredder 7.5 kW Double Shaft |

| Profit Drivers | Shred size control, transport, and compliance |

| Global Comparison | China shows advantage in copper/aluminum pricing |

| Future Trends | Smart, compact, energy-saving machines dominate |